Cheap tunnels can significantly improve the throughput of our transportation systems. To understand how, let's overview freight trains, passenger trains, trucks, cars, and tunneling technology.

Freight Trains Versus Trucks

There are tradeoffs between trucks and trains.

Any land vehicle uses energy to overcome two forces - drag (air resistance) and rolling resistance from wheels.

-

Drag roughly increases at the square of the speed. The aerodynamics and size of the vehicle have a significant impact.

-

Rolling resistance is primarily from the deformation of wheels as they roll over the ground. Rubber tires have more rolling resistance than steel wheels. Rolling resistance scales linearly with the weight of the vehicle. Speed has little effect.

Rolling Resistance = Crr * N

Crr = Rolling Resistance Coefficient

N = Force from weight of vehicle

-

The rolling resistance coefficient changes based on wheel diameter, type of material, and the weight on the wheel. Steel railroad wheels have their coefficient decrease with higher loads. Rubber tires do not usually have the same advantage.

Trains with heavy loads traveling at moderate speeds are much more fuel-efficient than trucks because their steel wheels reduce rolling resistance. If we compare two high-speed, lightweight vehicles, drag dominates. Whether they use tires or rails has less impact on efficiency.

Trucks are much more flexible than trains because they can haul smaller loads and have access to the road network. Goods arrive faster on trucks. Trains transport large, heavy loads long distances. As a result, trains haul 40% of ton-miles but only 15% of freight value.

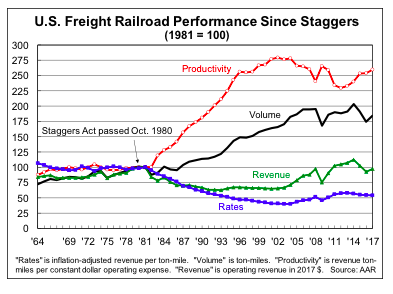

Precision Railroading

The maturation of the semi-truck and the interstate system was a colossal problem for railroads. There were over 200,000 railroad track miles in the 1970s, before a steep decline to 100,000 miles in the mid-1990s. In response to mounting bankruptcies, the government nationalized passenger rail (Amtrak) and deregulated freight rail. Railroads responded by doubling down on their best customers. Ton-miles roughly doubled from 1980 to 2020 even as tracks shrank. The changes railroads made became known as Precision Scheduled Railroading (PSR).

Source: sbecouncil.org

There are only seven Class 1 railroads in North America. One railroad executive, E. Hunter Harrison, was CEO at three of the seven companies and pioneered PSR. PSR abandons low-volume customers and focuses solely on volume shippers. Operating ratio, a measure of operating expenses compared to revenue, is the metric these companies strive to improve. PSR companies continually sell tracks and prune lesser customers to improve the operating ratio. Revenue increases come from general economic growth boosting demand for prized cargo like coal, ore, chemicals, grain, and cross-country intermodal.

There is only one Class 1 railroad that has not adopted PSR. That company is Burlington Northern Santa Fe (BNSF), controlled by Warren Buffet. It will take a bit of background to answer why.

Here is Buffet detailing why he and partner Charlie Munger decided to buy BNSF:

"Both of us are enthusiastic about BNSF's future because railroads have major cost and environmental advantages over trucking, their main competitor. Last year, BNSF moved each ton of freight it carried a record 500 miles on a single gallon of diesel fuel. That's three times more fuel-efficient than trucking is, which means our railroad owns an important advantage in operating costs. Concurrently, our country gains because of reduced greenhouse emissions and a much smaller need for imported oil. When traffic travels by rail, society benefits."

“Over time, the movement of goods in the United States will increase, and BNSF should get its full share of the gain,”

And comparing electric utilities and railroads:

"Finally, both require wise regulators who will provide certainty about allowable returns so that we can confidently make the huge investments required to maintain, replace and expand the plant."

Notice the implications in these statements about competition. Whether BNSF was more efficient than Union Pacific was not a concern. Railroads only indirectly compete with each other. Rail customers with bulky, low-value goods are beholden to railroads because trucking costs would make their businesses uneconomic. Buffet bought a company whose customers have limited options, guaranteeing returns.

Why Don't Railroads Compete More Directly?

Railroads get their moat from a combination of capital intensity and right-of-way.

Railroad track costs in the millions per mile to build before figuring in bridges, tunnels, and other geographic obstacles. In the heyday of railroad construction, some railroads would build lines right next to competitors. The vast majority of these lines merged because the maintenance cost alone is staggering.

Right-of-Way: the legal right, established by usage or grant, to pass along a specific route through grounds or property belonging to another

Railroads acquired almost all of their right-of-way 100-150 years ago through government grants, corruption, eminent domain, and private purchases. While new right-of-way may seem cost-effective, it is only so because of eminent domain. The acquirer uses government power to force sales of private land. It is infeasible to create a few hundred-mile rail line, let alone an entire network, buying right-of-way privately. Holdouts halt progress.

The downside of using eminent domain is that opposition becomes fierce and political, especially for a rail project that can bisect land parcels and is noisy. A perfect example comes from a group trying to build a private high-speed rail line from Houston to Dallas. Landowner opposition from the project has been intense enough to damage political backing and has invited a raft of anti-high speed rail bills in the coming Texas Legislature. Congressional representatives from districts along the rail line are trying to halt progress at the federal level.

The combination of capital intensity and difficulty of right-of-way acquisition creates a natural monopoly that only has indirect competition. Now we have our answer for why BNSF has not implemented Precision Railroading. Investors in the other big rail companies have short time horizons. They are willing to trade future profits for juicier dividends today by avoiding the cost of maintaining a low utilization track and right-of-way. Warren Buffet has a long time horizon and couldn't imagine giving up right-of-way that will likely earn increased rents from future economic growth.

Tunnels Make Right-of-Way Non-Rival

Economist Paul Romer pioneered the idea that ideas themselves are non-rival. Most goods are rival. If I'm using a specific refrigerator, no one else can have it in their house at the same time. They need a second refrigerator. Ideas can be used over and over by many people at the same time. Romer postulated that the non-rivalry of ideas is the driver of per capita economic growth. Ideas become more valuable as population and economies increase in size, but they never run out. He won a Nobel Prize for his efforts.

Despite how big in volume the Earth is and how expansive the universe is, humanity lives on a tiny portion of the planet's crust. Earth has a lot of gravity, which makes building elevated structures and tunneling challenging. Right-of-Ways become mostly a rival good as a result. If you cannot easily create new networks of right-of-ways, this is a chokepoint for economic growth.

Cheap tunneling technology makes right-of-way approximate a non-rival good. A tunnel that is 20 meters deep and 10,000 meters long with ramps to surface entrances might be 10,060 meters. Another tunnel 20 meters below that would be 10,120 meters. Each tunnel costs about the same to add. Instead of demolishing neighborhoods, you could move almost endless goods and people under existing right-of-way. Cheap tunnels create returns to scale for right-of-way and enable increased travel and goods consumption.

How Do You Make Cheap Tunnels?

There is one company that has made cheaper tunnels their mission, The Boring Company. The goal of the company is to tunnel faster than a snail moves.

A non-exhaustive list of cost reduction techniques:

-

Make the tunnel smaller.

Is it big enough to fit a vehicle or a shipping container? Great! Anything more is a waste. Area increases by the square of the radius. A slightly bigger tunnel means a lot more dirt to move.

-

Increase the power of the Tunnel Boring Machine (TBM).

Oil and gas drilling rigs can drill at speeds approaching one mile per day. Existing TBM designs do not have the power to match that. Engineering and logistics limit TBM drilling speed rather than physics.

-

Design the TBM to bore continuously.

Current TBMs can spend over half their day idle while boring soft soils. They have to stop and erect concrete support segments. Boring Company's next-gen TBM, Prufrock, is designed to erect support segments without stopping.

-

Stop using diesel locomotives in tunnels (and internal combustion engine vehicles).

Do you think it is a good idea to run a combustion engine in an enclosed space like a garage? Well, that is what current tunneling companies do. Diesel locomotives haul the dirt out. Excess ventilation is required to prevent workers from suffocating. Using electric powertrains allows more vehicles to haul dirt out without spending more on ventilation systems. Faster boring requires more dirt hauling!

-

Have the TBM start from the surface instead of using a launch pit.

Current TBMs have to start tunneling below grade. Starting a project means digging and lining a giant pit, then lowering the TBM and putting it together for operation. Prufrock tunnels from the surface, eliminating the launch pit.

Launch Pit w/ Gary the Snail. Source: The Boring Company

Prufrock starting to tunnel. Source: The Boring Company

-

Use above-ground stations.

Remember a few years ago when NYC's new subway extension cost billions per mile? A big part of that was giant underground stations. Small footprint surface stations are simple since Prufrock can create ramps. The only thing underground is standardized tunnels.

Source: The Boring Company

-

Use existing electric cars as vehicles instead of specialized train rolling stock.

Dedicated passenger rolling stock is expensive. Cars are mass-produced items.

A 10 car plus locomotive passenger train could hold 1000 people with a very squished seating or partial stand up. It would cost roughly $25 million to purchase. That would be $25,000 per person of capacity. An NYC subway car with 75% standing room is $10,000 per person.

A Model 3 costs ~$40,000 and seats four passengers in a Boring Company Loop system. $10,000 per person of capacity. A minibus with standing passengers would be even cheaper.

A Model 3 has wheels, removing the need for rails, and also carries a battery that eliminates the need for an electrical system (like a "third rail") to run the vehicle. Electrification of these systems can cost millions of dollars per mile. Rails alone cost $1-$2 million per mile.

-

Use the excavated dirt to make bricks.

Instead of hauling off the dirt to a dump, try to make it something valuable. Dirt haul cost per foot does not decrease with increased tunneling speed.

-

Reduce labor required to run the TBM

Automate as much of the TBM operation as feasible.

These ideas may seem basic, but consider that there are very few tunneling companies and that the buyers are almost exclusively government entities. There has been close to zero market pressure for innovation.

Let's Talk Capacity per Dollar

A year ago, The Boring Company temporarily posted a cost calculator (probably on accident). These figures are before many of the above strategies have been implemented.

The numbers were:

- $2.5 million mobilization

- $5.5-$8 million per mile for bare, lined tunnel

- $10-$14 million per mile of Loop tunnel, including road surface, lighting, ventilation, cameras, etc.

- $3-$6 million for an above-ground station

- $20-$40 million for a below-ground station

Boring Company has one awarded project with public numbers, a Loop System at the Las Vegas Convention Center (LVCC). Loop is simply "Teslas in Tunnels." Tesla submitted a fixed price bid of $50 million conditional on achieving capacity goals of 4000 passengers per hour.

The LVCC project included 2 miles of tunnel, two above-ground stations, and one underground station. If we use the calculator numbers, the estimate range is $50-$80 million, right in line. The Boring Company completed the project and verified the capacity in June 2021.

Imagine a hypothetical system that is 10 miles long with three stations and 30,000 passengers per hour per direction, comparable to a subway. Each tunnel can carry 2000 people per hour per direction, meaning the project requires 300 miles of tunnel. The total cost would be between $300 million and $400 million per mile. It turns out the stations are so cheap that you could have 30 of them and barely impact the price.

That is dramatically cheaper than recent US subway projects and comparable to the low end of other OECD countries. Boring Company based the LVCC project pricing on a slightly modified sewer tunnel boring machine, Godot+. Prufrock is six times faster at 1 mile per week. And the medium-term goal for Prufrock is to bore 7 miles per week. A cost decrease of 50%-60% with no other savings across the operation is possible with this tunneling speed. There are opportunities to increase passenger throughput with more optimized vehicles and tighter vehicle spacing. Boring Company achieved 2000 passengers per hour in each direction with six seconds of spacing between cars. Reducing spacing reduces CAPEX per capacity unit.

Loop is a Point-to-Point System

Instead of stacking tunnels on top of each other to mimic a subway, you could build a point-to-point network. The nature of using cars allows point-to-point travel, like an underground Uber, drastically cutting customer travel time.

Trains require large stations. They use a large amount of surface land or are very expensive to bury. The cost of loop stations is so cheap that you can place them next to any number of desirable locations.

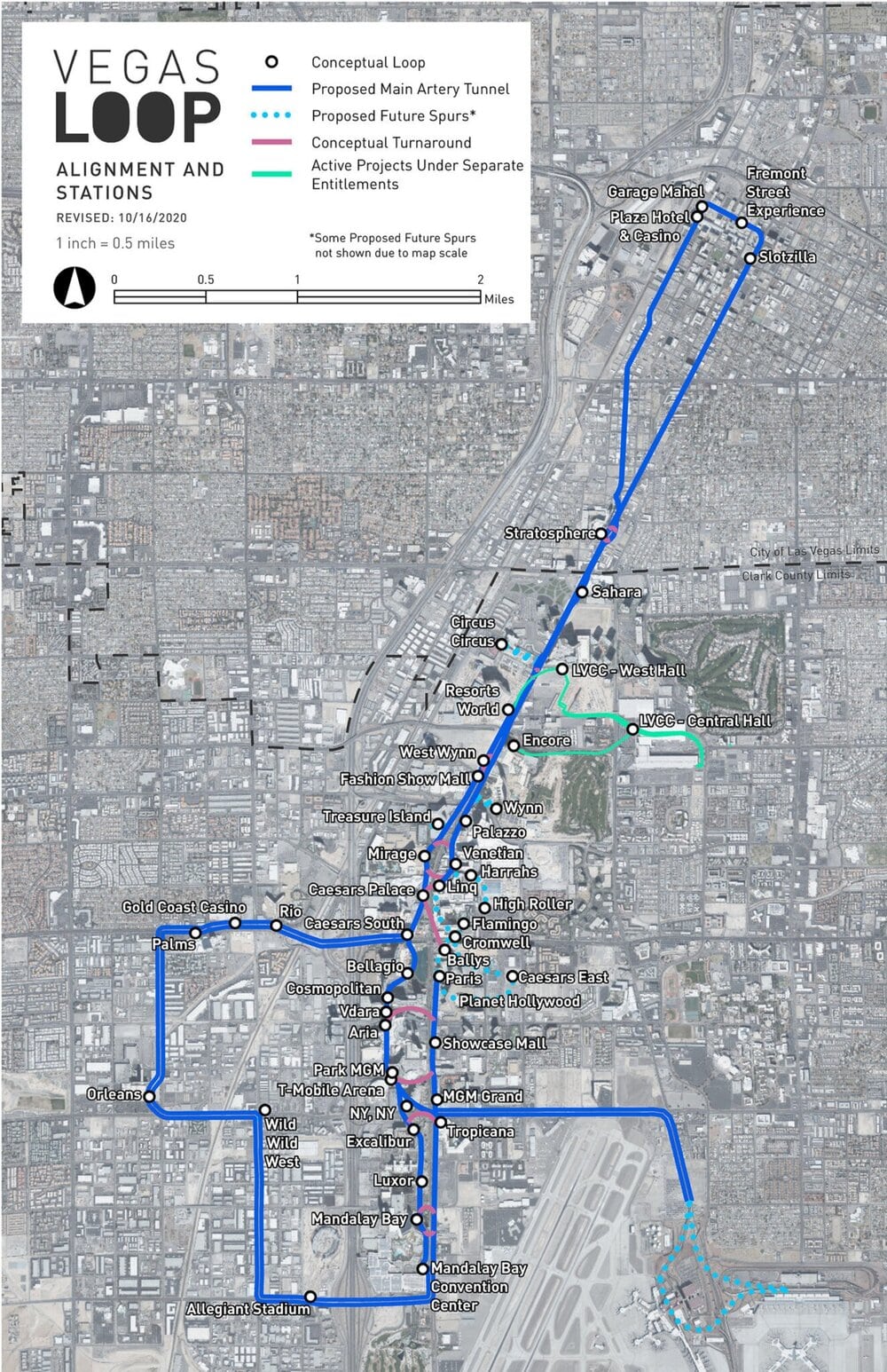

Las Vegas Loop

After The Boring Company (TBC) won the LVCC contract, it realized Las Vegas could be a perfect site to prove its technology. TBC released plans to connect the entire strip from the airport to downtown Las Vegas. Las Vegas offers several advantages:

-

The Strip is congested, and demand for this service would be high.

-

The right-of-ways are owned by the city and county and have limited requirements for environmental impact studies. The governments are motivated to improve transportation.

-

Casino groups own much of the private land and are willing to foot the cost of stations.

-

Along the strip, a high proportion of travel happens in taxis. So paid drivers or tunnel system-bound cars would be competitive without the need for completely autonomous vehicles.

-

It is Las Vegas.

Tunnels allow the Las Vegas Loop to start small. TBC will tunnel from the convention center to the nearby Resorts World Casino and construct another to Encore. These tunnels will be the first production tunnels dug by Prufrock.

Source: The Boring Company

Source: The Boring Company

Loop is Like Adding Toll Lanes

Virginia recently approved a $595 million project to add two reversible 10-mile express lanes within the I-95 right-of-way. If we pull out our handy Boring Company calculator, we get a cost between $230 and $340 million for 20 miles worth of tunnel. And entrances do not have to be on I-95. The project is not state-funded. A private company will build it and earn back its investment from charging tolls.

Tunnels could expand the I-95 corridor's capacity further without using eminent domain, with zero traffic disruption, at zero cost to the taxpayers, and at a cost likely much cheaper than our year-old estimates by using Prufrock. Commuters value their time so highly they will pay tolls high enough to justify a $595 million project. Adding the same incremental capacity at what could be 1/4 the price is a classic no-brainer.

Get Rid of Scarcity Mindset

One example of criticism is the WVU Personal Rapid Transit (PRT) project. Planners envisioned WVU PRT to take riders directly to their destination. The project ended up with five stations and suffered budget overruns. At peak demand, trams run a scheduled route like a train to increase capacity. The constraints of land availability, high CAPEX, and fares not covering operating costs make this a reasonable tradeoff.

With cheap tunnels funded by user fares, this same logic does not necessarily apply. Tunnel builders will keep adding capacity until the willingness of customers to pay for express service is satisfied. If the two express lanes in Northern Virginia are any indication, this demand is extreme in many regions.

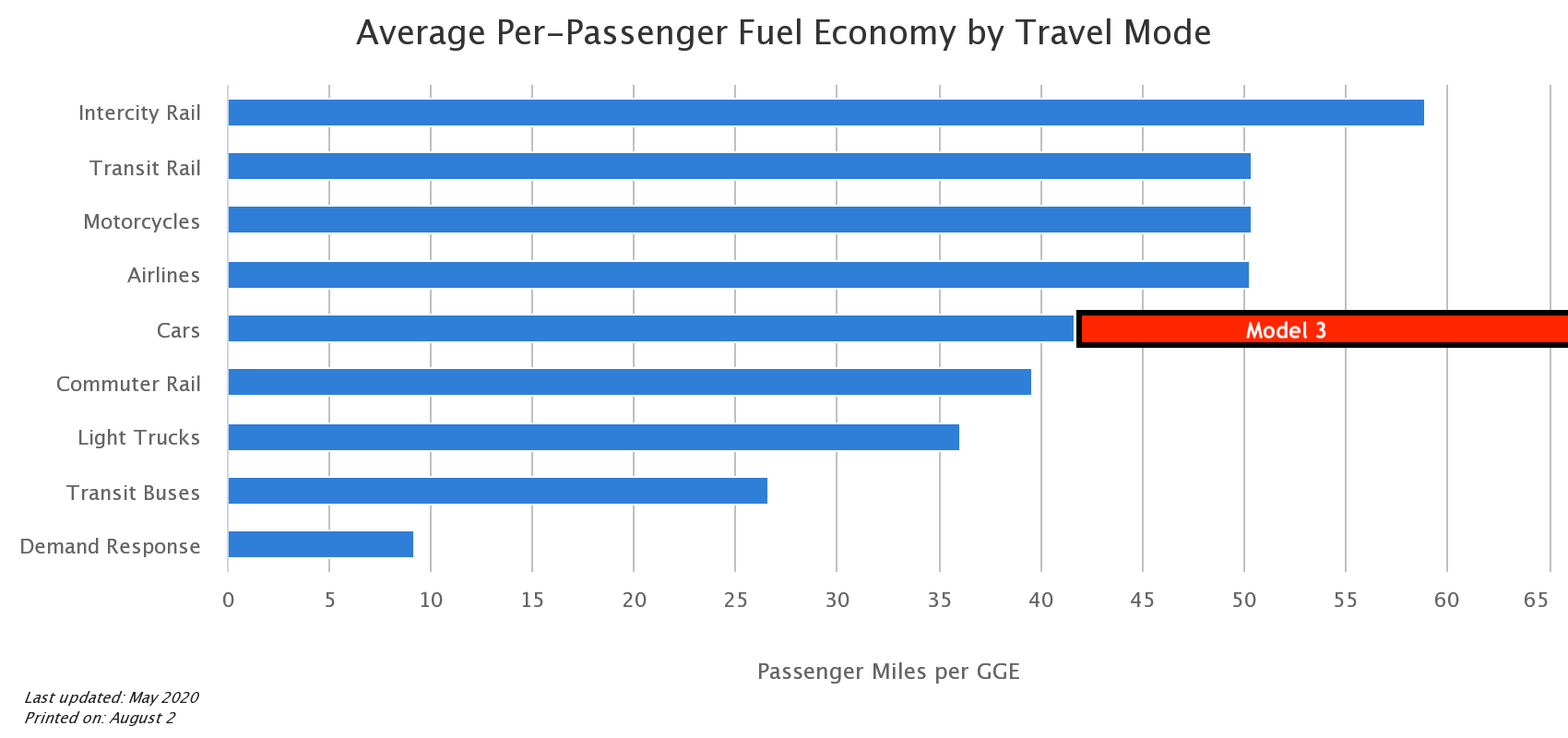

Trains are more efficient?

Efficiency matters for operating costs. Remember that a train's fuel efficiency advantage comes from reduced rolling resistance. A passenger train car is mostly air inside instead of coal or iron ore, eroding that advantage. Electric vehicles are many times more efficient than gasoline cars. A Model 3 will have much better fuel efficiency than a typical train.

Source: energy.gov, annotations by author

Source: energy.gov, annotations by author

The highest theoretical efficiency mode is an electric bus. Buses score so poorly on the average efficiency because they run empty so often.

Transportation Access

But if you only build tunnels for paying customers, what about those who can't afford it? First, the regular roads will have reduced congestion. Second, transit technologies are chosen based on popularity, not practicality. For most towns and cities in the US, Bus Rapid Transit (BRT), protected bike lanes, and a few small, specialized services can solve access. BRT has the throughput of a subway at a fraction of the capital and operating cost. Bike lanes connect lower density routes to BRT. Small, specialized services take care of ADA customers. BRT is not like regular buses. Fares are paid ahead of time at stops configured like subway stations. BRT lines have dedicated lanes and traffic light synchronization to keep speeds up. Everyone has speedy transit for the lowest overall cost. Putting people that want express service in tunnels makes providing BRT and bike lane infrastructure easier.

Politics of Trains

Due to the need for controversial surface right-of-way and high capital costs, trains and subways are political footballs.

- Politicians always want more stations for their constituents, raising costs and slowing down average speeds

- Fares rarely cover operating expenses, let alone capital improvements. Almost every US transit agency is between 10% and 60% coverage of operating expenses. Amtrak is the fiscal leader at 95% coverage, including partner payments from states.

- Landowners hate surface trains crossing their property.

Compare this to Loop Tunnels:

- Adding stations is inexpensive and does not slow down the system

- People value fast, personal transport and are willing to pay for it.

- The vast majority of landowners will not need to provide access to their land or have their land disturbed in any way. Tunnels can go under existing right-of-ways similar to fiber optic cables, without the trenching!

Car Tunnels vs. Micro-mobility

E-scooters, E-bikes, hoverboards, and other light electric vehicles have taken off over the last few years. Did you know that the batteries in one Model 3 can power hundreds of E-bikes? Or that the throughput of a bike lane is 5x that of a car lane?

These vehicles, popularized as micro-mobility, are neat and fun. Many people will choose to ride them. But they also top out under 30 MPH. The speed limits practical travel range and opportunities.

That is why cars and micromobility need competition, not coercion. Free car parking? Bad. Removing all parking and banning cars? Also bad.

Traffic congestion from cars is a negative for society. Allowing fare-funded tunnels to expand traffic capacity is pro-growth and expands human range. Removing cars from cities and forcing people to use micromobility and limited transit options is a form of degrowth. We can build more batteries, more cars, and more tunnels. And humans will be better off for it.

Future Possibilities

Tunnels are more than just Loop.

Hyperloop

In 2013 Elon Musk released a concept for high-speed travel known as Hyperloop. Pods travel at 700 MPH in tubes between city pairs. The proposed first route was between Los Angeles and San Francisco, where the travel time would be 30 minutes. The system would cost 1/10 of the proposed high-speed rail project that had journey times five times longer. The fare cost required for breakeven was $20.

Hyperloop achieves this speed by reducing the air pressure in the tube, reducing drag. The individual vehicles do not use wheels. They levitate using compressed air bearings or like a maglev train. This reduced resistance means that once the pod is accelerated, it only needs boosting about every 70 miles. Less than 1% of the track requires a third rail. Operating costs are low because the energy per passenger mile is lower than trains, planes, or cars.

The original proposal assumed an elevated tube. Cheap tunneling has changed the math. Tunneling provides a big diameter that decreases the technical challenges for the vehicle, reduces surface impact, and eliminates risk from earthquakes.

The physical tube and pylon construction was $3.8 billion out of the $6 billion total project cost. Because of the nature of the Hyperloop, the tunnels are much simpler than the current Loop tunnels. Cost estimates will use bare tunnel costs. Our year-old estimates using Godot+ come in at $4.3 to $6.2 billion. Even past tunneling costs are competitive with the high-speed rail.

SpaceX built a one-kilometer test tube outside its California headquarters. Thousands of university teams applied to be in Hyperloop contests held from 2015-2019. The best teams would build their prototype and get to test it, typically raising the required $10,000-$20,000 themselves. Each year the difficulty increased. The winning team in 2019 had a high speed of 287 MPH, as fast as some of the world's fastest bullet trains. A malfunction kept them from their projected 385 MPH. The competition will continue once a 6.2-mile test track is complete.

Virgin Hyperloop is another company pursuing a similar design. It has a human-rated pod that has gone up to 250 MPH in its 500-meter test tube. In late 2020, they successfully tested a pod with humans inside. A 6-mile test tube is planned in West Virginia to certify the system for commercial use.

A 6-mile test tube allows a pod to reach full speed and then stop at human appropriate acceleration and deceleration.

The primary focus for Boring Company is reducing the cost of their tunnels and earning revenue from small applications as they scale tunneling capacity. Because Hyperloop has simple tunnels, its economics will dramatically improve as tunneling costs decrease.

Moving Goods in Freight Tunnels

Competing against freight trains and trucks is tougher than competing against passenger trains and gridlock because cost is so important. TBC's current plans involve using an electric, sled-like vehicle to carry a standard shipping container.

One growth area for railroads over the last two decades has been intermodal. Intermodal is shipping containers that use trains for part of their journey. For railroads to be competitive at intermodal shipping, the containers must be double stacked. Railroads and governments are spending billions of dollars so rail corridors can accommodate double-stacked containers (tunnels and bridges are often too short).

An early application for tunnels could be competing with trucks to service the intermodal terminals in congested areas. Busy ports would be a great example, where trucks travel relatively short distances from ship terminals to intermodal rail terminals. Because rail lines are basically in the same place as 150 years ago, a less disruptive system that can complement the rail network would be valuable. The sleds will have cheaper labor costs and lower fuel costs than diesel trucks, helping to justify the capital expense of tunnels.

Like Hyperloop, the freight tunnels are much simpler than Loop tunnels. Tunneling improvements will have a significant impact on the total cost. As these costs decrease, tunnels could transform from a niche into a network providing competition against trucks and trains. It is easy to imagine regional systems transporting containers by sled linked together by long-distance mainlines outfitted with rails, transporting goods point to point for cheaper than trucks. In crowded cities, the number of goods flowing in and out can increase dramatically compared to the limits of surface streets, raising the standard of living.

Bring on the Tunnels

Boring Company tunnels are at a price point where demand has outstripped supply. The competing bidder for the LVCC contract was a traditional people mover system that cost $215 million, over 4x the $50 million Boring Company cost. Local loops, pedestrian tunnels, and utility tunnels are examples of small projects that will provide revenue for growth and practice tunneling. The constraints are manufacturing boring machines, right-of-way, and environmental reviews.

The machine constraint is easier to solve. Besides building more at the factory, increased speed improves output dramatically. Two hundred machines could bore two tunnels under every interstate in 10 years at current rates. At Prufrock's medium-term speed goal, it would take less than two years.

Building a new high-speed transportation system without using government right-of-ways is close to impossible. There needs to be a system to auction off slivers of 3D tunneling rights.

Environmental reviews are more challenging. At first, site selection can avoid federal right-of-ways that trigger the National Environmental Protection Act (NEPA). Building a nationwide network requires reform or clarification. Fiber optic cables have a NEPA exemption known as a programmatic environmental assessment. Laying cable is a repetitive process, and guessing the impact based on the footage without a specific study is acceptable. Tunnels have similar qualities and need the same exemption.

I know mid-century modern is popular right now, but yearning for slow 1960s technology like high-speed rail is lame. Hyperloops and freight tunnels can create super regions and minimize the physical movement of people and goods as a constraint on growth. Commuting daily to a job 300 miles away should be normal. The technology is maturing before our eyes, and the costs are only going to fall. So bring on the tunnels!

-

Hyperloop White Paper

-

SpaceX Hyperloop Competition

Tunnels are our Transportation Future

2021 August 2 Twitter Substack See all postsTunnels are getting cheap and that makes a big difference.

Cheap tunnels can significantly improve the throughput of our transportation systems. To understand how, let's overview freight trains, passenger trains, trucks, cars, and tunneling technology.

Freight Trains Versus Trucks

There are tradeoffs between trucks and trains.

Any land vehicle uses energy to overcome two forces - drag (air resistance) and rolling resistance from wheels.

Drag roughly increases at the square of the speed. The aerodynamics and size of the vehicle have a significant impact.

Rolling resistance is primarily from the deformation of wheels as they roll over the ground. Rubber tires have more rolling resistance than steel wheels. Rolling resistance scales linearly with the weight of the vehicle. Speed has little effect.

The rolling resistance coefficient changes based on wheel diameter, type of material, and the weight on the wheel. Steel railroad wheels have their coefficient decrease with higher loads. Rubber tires do not usually have the same advantage.

Trains with heavy loads traveling at moderate speeds are much more fuel-efficient than trucks because their steel wheels reduce rolling resistance. If we compare two high-speed, lightweight vehicles, drag dominates. Whether they use tires or rails has less impact on efficiency.

Trucks are much more flexible than trains because they can haul smaller loads and have access to the road network. Goods arrive faster on trucks. Trains transport large, heavy loads long distances. As a result, trains haul 40% of ton-miles but only 15% of freight value.

Precision Railroading

The maturation of the semi-truck and the interstate system was a colossal problem for railroads. There were over 200,000 railroad track miles in the 1970s, before a steep decline to 100,000 miles in the mid-1990s. In response to mounting bankruptcies, the government nationalized passenger rail (Amtrak) and deregulated freight rail. Railroads responded by doubling down on their best customers. Ton-miles roughly doubled from 1980 to 2020 even as tracks shrank. The changes railroads made became known as Precision Scheduled Railroading (PSR).

Source: sbecouncil.org

There are only seven Class 1 railroads in North America. One railroad executive, E. Hunter Harrison, was CEO at three of the seven companies and pioneered PSR. PSR abandons low-volume customers and focuses solely on volume shippers. Operating ratio, a measure of operating expenses compared to revenue, is the metric these companies strive to improve. PSR companies continually sell tracks and prune lesser customers to improve the operating ratio. Revenue increases come from general economic growth boosting demand for prized cargo like coal, ore, chemicals, grain, and cross-country intermodal.

There is only one Class 1 railroad that has not adopted PSR. That company is Burlington Northern Santa Fe (BNSF), controlled by Warren Buffet. It will take a bit of background to answer why.

Here is Buffet detailing why he and partner Charlie Munger decided to buy BNSF:

And comparing electric utilities and railroads:

Notice the implications in these statements about competition. Whether BNSF was more efficient than Union Pacific was not a concern. Railroads only indirectly compete with each other. Rail customers with bulky, low-value goods are beholden to railroads because trucking costs would make their businesses uneconomic. Buffet bought a company whose customers have limited options, guaranteeing returns.

Why Don't Railroads Compete More Directly?

Railroads get their moat from a combination of capital intensity and right-of-way.

Railroad track costs in the millions per mile to build before figuring in bridges, tunnels, and other geographic obstacles. In the heyday of railroad construction, some railroads would build lines right next to competitors. The vast majority of these lines merged because the maintenance cost alone is staggering.

Railroads acquired almost all of their right-of-way 100-150 years ago through government grants, corruption, eminent domain, and private purchases. While new right-of-way may seem cost-effective, it is only so because of eminent domain. The acquirer uses government power to force sales of private land. It is infeasible to create a few hundred-mile rail line, let alone an entire network, buying right-of-way privately. Holdouts halt progress.

The downside of using eminent domain is that opposition becomes fierce and political, especially for a rail project that can bisect land parcels and is noisy. A perfect example comes from a group trying to build a private high-speed rail line from Houston to Dallas. Landowner opposition from the project has been intense enough to damage political backing and has invited a raft of anti-high speed rail bills in the coming Texas Legislature. Congressional representatives from districts along the rail line are trying to halt progress at the federal level.

The combination of capital intensity and difficulty of right-of-way acquisition creates a natural monopoly that only has indirect competition. Now we have our answer for why BNSF has not implemented Precision Railroading. Investors in the other big rail companies have short time horizons. They are willing to trade future profits for juicier dividends today by avoiding the cost of maintaining a low utilization track and right-of-way. Warren Buffet has a long time horizon and couldn't imagine giving up right-of-way that will likely earn increased rents from future economic growth.

Tunnels Make Right-of-Way Non-Rival

Economist Paul Romer pioneered the idea that ideas themselves are non-rival. Most goods are rival. If I'm using a specific refrigerator, no one else can have it in their house at the same time. They need a second refrigerator. Ideas can be used over and over by many people at the same time. Romer postulated that the non-rivalry of ideas is the driver of per capita economic growth. Ideas become more valuable as population and economies increase in size, but they never run out. He won a Nobel Prize for his efforts.

Despite how big in volume the Earth is and how expansive the universe is, humanity lives on a tiny portion of the planet's crust. Earth has a lot of gravity, which makes building elevated structures and tunneling challenging. Right-of-Ways become mostly a rival good as a result. If you cannot easily create new networks of right-of-ways, this is a chokepoint for economic growth.

Cheap tunneling technology makes right-of-way approximate a non-rival good. A tunnel that is 20 meters deep and 10,000 meters long with ramps to surface entrances might be 10,060 meters. Another tunnel 20 meters below that would be 10,120 meters. Each tunnel costs about the same to add. Instead of demolishing neighborhoods, you could move almost endless goods and people under existing right-of-way. Cheap tunnels create returns to scale for right-of-way and enable increased travel and goods consumption.

How Do You Make Cheap Tunnels?

There is one company that has made cheaper tunnels their mission, The Boring Company. The goal of the company is to tunnel faster than a snail moves.

A non-exhaustive list of cost reduction techniques:

Make the tunnel smaller.

Is it big enough to fit a vehicle or a shipping container? Great! Anything more is a waste. Area increases by the square of the radius. A slightly bigger tunnel means a lot more dirt to move.

Increase the power of the Tunnel Boring Machine (TBM).

Oil and gas drilling rigs can drill at speeds approaching one mile per day. Existing TBM designs do not have the power to match that. Engineering and logistics limit TBM drilling speed rather than physics.

Design the TBM to bore continuously.

Current TBMs can spend over half their day idle while boring soft soils. They have to stop and erect concrete support segments. Boring Company's next-gen TBM, Prufrock, is designed to erect support segments without stopping.

Stop using diesel locomotives in tunnels (and internal combustion engine vehicles).

Do you think it is a good idea to run a combustion engine in an enclosed space like a garage? Well, that is what current tunneling companies do. Diesel locomotives haul the dirt out. Excess ventilation is required to prevent workers from suffocating. Using electric powertrains allows more vehicles to haul dirt out without spending more on ventilation systems. Faster boring requires more dirt hauling!

Have the TBM start from the surface instead of using a launch pit.

Current TBMs have to start tunneling below grade. Starting a project means digging and lining a giant pit, then lowering the TBM and putting it together for operation. Prufrock tunnels from the surface, eliminating the launch pit.

Launch Pit w/ Gary the Snail. Source: The Boring Company

Prufrock starting to tunnel. Source: The Boring Company

Use above-ground stations.

Remember a few years ago when NYC's new subway extension cost billions per mile? A big part of that was giant underground stations. Small footprint surface stations are simple since Prufrock can create ramps. The only thing underground is standardized tunnels.

Source: The Boring Company

Use existing electric cars as vehicles instead of specialized train rolling stock.

Dedicated passenger rolling stock is expensive. Cars are mass-produced items.

A 10 car plus locomotive passenger train could hold 1000 people with a very squished seating or partial stand up. It would cost roughly $25 million to purchase. That would be $25,000 per person of capacity. An NYC subway car with 75% standing room is $10,000 per person.

A Model 3 costs ~$40,000 and seats four passengers in a Boring Company Loop system. $10,000 per person of capacity. A minibus with standing passengers would be even cheaper.

A Model 3 has wheels, removing the need for rails, and also carries a battery that eliminates the need for an electrical system (like a "third rail") to run the vehicle. Electrification of these systems can cost millions of dollars per mile. Rails alone cost $1-$2 million per mile.

Use the excavated dirt to make bricks.

Instead of hauling off the dirt to a dump, try to make it something valuable. Dirt haul cost per foot does not decrease with increased tunneling speed.

Reduce labor required to run the TBM

Automate as much of the TBM operation as feasible.

These ideas may seem basic, but consider that there are very few tunneling companies and that the buyers are almost exclusively government entities. There has been close to zero market pressure for innovation.

Let's Talk Capacity per Dollar

A year ago, The Boring Company temporarily posted a cost calculator (probably on accident). These figures are before many of the above strategies have been implemented.

The numbers were:

Boring Company has one awarded project with public numbers, a Loop System at the Las Vegas Convention Center (LVCC). Loop is simply "Teslas in Tunnels." Tesla submitted a fixed price bid of $50 million conditional on achieving capacity goals of 4000 passengers per hour.

The LVCC project included 2 miles of tunnel, two above-ground stations, and one underground station. If we use the calculator numbers, the estimate range is $50-$80 million, right in line. The Boring Company completed the project and verified the capacity in June 2021.

Imagine a hypothetical system that is 10 miles long with three stations and 30,000 passengers per hour per direction, comparable to a subway. Each tunnel can carry 2000 people per hour per direction, meaning the project requires 300 miles of tunnel. The total cost would be between $300 million and $400 million per mile. It turns out the stations are so cheap that you could have 30 of them and barely impact the price.

That is dramatically cheaper than recent US subway projects and comparable to the low end of other OECD countries. Boring Company based the LVCC project pricing on a slightly modified sewer tunnel boring machine, Godot+. Prufrock is six times faster at 1 mile per week. And the medium-term goal for Prufrock is to bore 7 miles per week. A cost decrease of 50%-60% with no other savings across the operation is possible with this tunneling speed. There are opportunities to increase passenger throughput with more optimized vehicles and tighter vehicle spacing. Boring Company achieved 2000 passengers per hour in each direction with six seconds of spacing between cars. Reducing spacing reduces CAPEX per capacity unit.

Loop is a Point-to-Point System

Instead of stacking tunnels on top of each other to mimic a subway, you could build a point-to-point network. The nature of using cars allows point-to-point travel, like an underground Uber, drastically cutting customer travel time.

Trains require large stations. They use a large amount of surface land or are very expensive to bury. The cost of loop stations is so cheap that you can place them next to any number of desirable locations.

Las Vegas Loop

After The Boring Company (TBC) won the LVCC contract, it realized Las Vegas could be a perfect site to prove its technology. TBC released plans to connect the entire strip from the airport to downtown Las Vegas. Las Vegas offers several advantages:

The Strip is congested, and demand for this service would be high.

The right-of-ways are owned by the city and county and have limited requirements for environmental impact studies. The governments are motivated to improve transportation.

Casino groups own much of the private land and are willing to foot the cost of stations.

Along the strip, a high proportion of travel happens in taxis. So paid drivers or tunnel system-bound cars would be competitive without the need for completely autonomous vehicles.

It is Las Vegas.

Tunnels allow the Las Vegas Loop to start small. TBC will tunnel from the convention center to the nearby Resorts World Casino and construct another to Encore. These tunnels will be the first production tunnels dug by Prufrock.

Loop is Like Adding Toll Lanes

Virginia recently approved a $595 million project to add two reversible 10-mile express lanes within the I-95 right-of-way. If we pull out our handy Boring Company calculator, we get a cost between $230 and $340 million for 20 miles worth of tunnel. And entrances do not have to be on I-95. The project is not state-funded. A private company will build it and earn back its investment from charging tolls.

Tunnels could expand the I-95 corridor's capacity further without using eminent domain, with zero traffic disruption, at zero cost to the taxpayers, and at a cost likely much cheaper than our year-old estimates by using Prufrock. Commuters value their time so highly they will pay tolls high enough to justify a $595 million project. Adding the same incremental capacity at what could be 1/4 the price is a classic no-brainer.

Get Rid of Scarcity Mindset

One example of criticism is the WVU Personal Rapid Transit (PRT) project. Planners envisioned WVU PRT to take riders directly to their destination. The project ended up with five stations and suffered budget overruns. At peak demand, trams run a scheduled route like a train to increase capacity. The constraints of land availability, high CAPEX, and fares not covering operating costs make this a reasonable tradeoff.

With cheap tunnels funded by user fares, this same logic does not necessarily apply. Tunnel builders will keep adding capacity until the willingness of customers to pay for express service is satisfied. If the two express lanes in Northern Virginia are any indication, this demand is extreme in many regions.

Trains are more efficient?

Efficiency matters for operating costs. Remember that a train's fuel efficiency advantage comes from reduced rolling resistance. A passenger train car is mostly air inside instead of coal or iron ore, eroding that advantage. Electric vehicles are many times more efficient than gasoline cars. A Model 3 will have much better fuel efficiency than a typical train.

The highest theoretical efficiency mode is an electric bus. Buses score so poorly on the average efficiency because they run empty so often.

Transportation Access

But if you only build tunnels for paying customers, what about those who can't afford it? First, the regular roads will have reduced congestion. Second, transit technologies are chosen based on popularity, not practicality. For most towns and cities in the US, Bus Rapid Transit (BRT), protected bike lanes, and a few small, specialized services can solve access. BRT has the throughput of a subway at a fraction of the capital and operating cost. Bike lanes connect lower density routes to BRT. Small, specialized services take care of ADA customers. BRT is not like regular buses. Fares are paid ahead of time at stops configured like subway stations. BRT lines have dedicated lanes and traffic light synchronization to keep speeds up. Everyone has speedy transit for the lowest overall cost. Putting people that want express service in tunnels makes providing BRT and bike lane infrastructure easier.

Politics of Trains

Due to the need for controversial surface right-of-way and high capital costs, trains and subways are political footballs.

Compare this to Loop Tunnels:

Car Tunnels vs. Micro-mobility

E-scooters, E-bikes, hoverboards, and other light electric vehicles have taken off over the last few years. Did you know that the batteries in one Model 3 can power hundreds of E-bikes? Or that the throughput of a bike lane is 5x that of a car lane?

These vehicles, popularized as micro-mobility, are neat and fun. Many people will choose to ride them. But they also top out under 30 MPH. The speed limits practical travel range and opportunities.

That is why cars and micromobility need competition, not coercion. Free car parking? Bad. Removing all parking and banning cars? Also bad.

Traffic congestion from cars is a negative for society. Allowing fare-funded tunnels to expand traffic capacity is pro-growth and expands human range. Removing cars from cities and forcing people to use micromobility and limited transit options is a form of degrowth. We can build more batteries, more cars, and more tunnels. And humans will be better off for it.

Future Possibilities

Tunnels are more than just Loop.

Hyperloop

In 2013 Elon Musk released a concept for high-speed travel known as Hyperloop. Pods travel at 700 MPH in tubes between city pairs. The proposed first route was between Los Angeles and San Francisco, where the travel time would be 30 minutes. The system would cost 1/10 of the proposed high-speed rail project that had journey times five times longer. The fare cost required for breakeven was $20.

Hyperloop achieves this speed by reducing the air pressure in the tube, reducing drag. The individual vehicles do not use wheels. They levitate using compressed air bearings or like a maglev train. This reduced resistance means that once the pod is accelerated, it only needs boosting about every 70 miles. Less than 1% of the track requires a third rail. Operating costs are low because the energy per passenger mile is lower than trains, planes, or cars.

The original proposal assumed an elevated tube. Cheap tunneling has changed the math. Tunneling provides a big diameter that decreases the technical challenges for the vehicle, reduces surface impact, and eliminates risk from earthquakes.

The physical tube and pylon construction was $3.8 billion out of the $6 billion total project cost. Because of the nature of the Hyperloop, the tunnels are much simpler than the current Loop tunnels. Cost estimates will use bare tunnel costs. Our year-old estimates using Godot+ come in at $4.3 to $6.2 billion. Even past tunneling costs are competitive with the high-speed rail.

SpaceX built a one-kilometer test tube outside its California headquarters. Thousands of university teams applied to be in Hyperloop contests held from 2015-2019. The best teams would build their prototype and get to test it, typically raising the required $10,000-$20,000 themselves. Each year the difficulty increased. The winning team in 2019 had a high speed of 287 MPH, as fast as some of the world's fastest bullet trains. A malfunction kept them from their projected 385 MPH. The competition will continue once a 6.2-mile test track is complete.

Virgin Hyperloop is another company pursuing a similar design. It has a human-rated pod that has gone up to 250 MPH in its 500-meter test tube. In late 2020, they successfully tested a pod with humans inside. A 6-mile test tube is planned in West Virginia to certify the system for commercial use.

A 6-mile test tube allows a pod to reach full speed and then stop at human appropriate acceleration and deceleration.

The primary focus for Boring Company is reducing the cost of their tunnels and earning revenue from small applications as they scale tunneling capacity. Because Hyperloop has simple tunnels, its economics will dramatically improve as tunneling costs decrease.

Moving Goods in Freight Tunnels

Competing against freight trains and trucks is tougher than competing against passenger trains and gridlock because cost is so important. TBC's current plans involve using an electric, sled-like vehicle to carry a standard shipping container.

One growth area for railroads over the last two decades has been intermodal. Intermodal is shipping containers that use trains for part of their journey. For railroads to be competitive at intermodal shipping, the containers must be double stacked. Railroads and governments are spending billions of dollars so rail corridors can accommodate double-stacked containers (tunnels and bridges are often too short).

An early application for tunnels could be competing with trucks to service the intermodal terminals in congested areas. Busy ports would be a great example, where trucks travel relatively short distances from ship terminals to intermodal rail terminals. Because rail lines are basically in the same place as 150 years ago, a less disruptive system that can complement the rail network would be valuable. The sleds will have cheaper labor costs and lower fuel costs than diesel trucks, helping to justify the capital expense of tunnels.

Like Hyperloop, the freight tunnels are much simpler than Loop tunnels. Tunneling improvements will have a significant impact on the total cost. As these costs decrease, tunnels could transform from a niche into a network providing competition against trucks and trains. It is easy to imagine regional systems transporting containers by sled linked together by long-distance mainlines outfitted with rails, transporting goods point to point for cheaper than trucks. In crowded cities, the number of goods flowing in and out can increase dramatically compared to the limits of surface streets, raising the standard of living.

Bring on the Tunnels

Boring Company tunnels are at a price point where demand has outstripped supply. The competing bidder for the LVCC contract was a traditional people mover system that cost $215 million, over 4x the $50 million Boring Company cost. Local loops, pedestrian tunnels, and utility tunnels are examples of small projects that will provide revenue for growth and practice tunneling. The constraints are manufacturing boring machines, right-of-way, and environmental reviews.

The machine constraint is easier to solve. Besides building more at the factory, increased speed improves output dramatically. Two hundred machines could bore two tunnels under every interstate in 10 years at current rates. At Prufrock's medium-term speed goal, it would take less than two years.

Building a new high-speed transportation system without using government right-of-ways is close to impossible. There needs to be a system to auction off slivers of 3D tunneling rights.

Environmental reviews are more challenging. At first, site selection can avoid federal right-of-ways that trigger the National Environmental Protection Act (NEPA). Building a nationwide network requires reform or clarification. Fiber optic cables have a NEPA exemption known as a programmatic environmental assessment. Laying cable is a repetitive process, and guessing the impact based on the footage without a specific study is acceptable. Tunnels have similar qualities and need the same exemption.

I know mid-century modern is popular right now, but yearning for slow 1960s technology like high-speed rail is lame. Hyperloops and freight tunnels can create super regions and minimize the physical movement of people and goods as a constraint on growth. Commuting daily to a job 300 miles away should be normal. The technology is maturing before our eyes, and the costs are only going to fall. So bring on the tunnels!

Hyperloop White Paper

SpaceX Hyperloop Competition